In the robotic groove cutting industry, welding robots face similar challenges. Minyue technology's "Non-Teach" solution effectively helps customers to solve the pain points in the industry, and it has been promoted and applied in a leading enterprise of engineering machinery. With the trend of flexible production, easily use, automation and intelligent level must be improved for robotic . Minyue Technology intelligent welding robot platform is adhering to the product concept of "can use and easily use ", enabling the application for groove cutting industry and assist users in manufacturing upgrading.

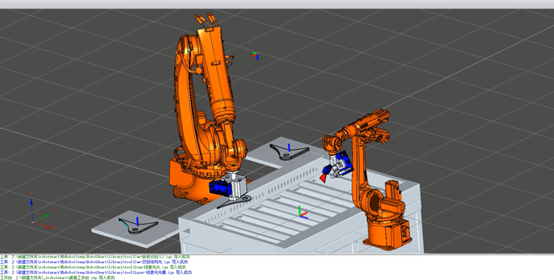

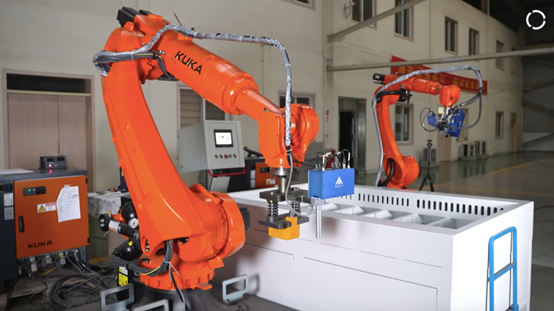

Non-Teach robotic groove cutting workstation

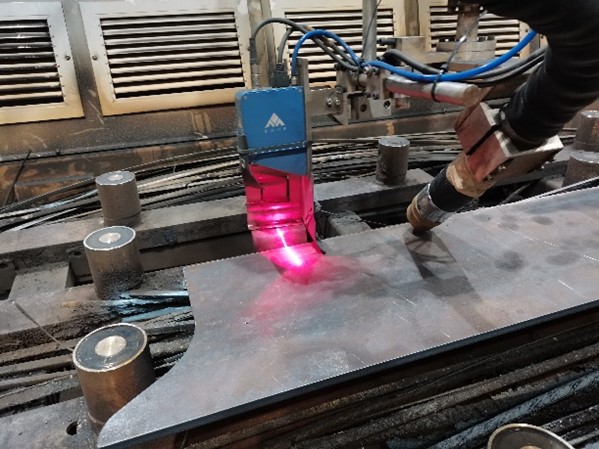

Actual cutting effect

Minyue technology non-teach intelligent groove cutting solution which realizes one-button simple operation.Groove cutting based on offline programming and visual sensingis equivalent to unmanned in robot industry!This solution has three significant advantages:

The first point: Free people from complex programming. Before production, using off-line programming software and according to CAD drawings, it will do the automatic trajectory planning and generate the cutting trajectory. In the process of production. The large field binocular camera is used to achieve rough positioning, and the laser is used to accurately correct the cutting trajectory. This solution can fundamentally solve the problem of workpiece deformation and inconsistency.

Second point: it integrate with a rich welding process library, including flame cutting and plasma cutting etc. Through cutting edge, plate thickness, material, groove angle, truncated edge, it will automatically determine the air flow, voltage and current parameters in cutting process without manual intervention.

Third point , it provides a perfect solution that can adapt to the demands of groove cutting in different occasions, including single robot of cutting workstation for small and medium-sized workpiece, dual-robot of feeding,unloading,cutting workstation and groove cutting workstation for large workpiece.