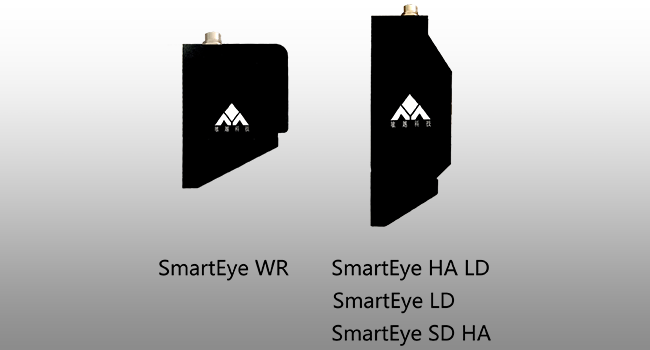

1.It can output high-quality 3D data for a variety of metal workpiece, which can meet the diverse requirements of anti-environmental light, high precision, high speed and small volume in different requests.

2.Can be high precision, high speed, customizable, the field of vision can meet the actual needs of typical scenes.

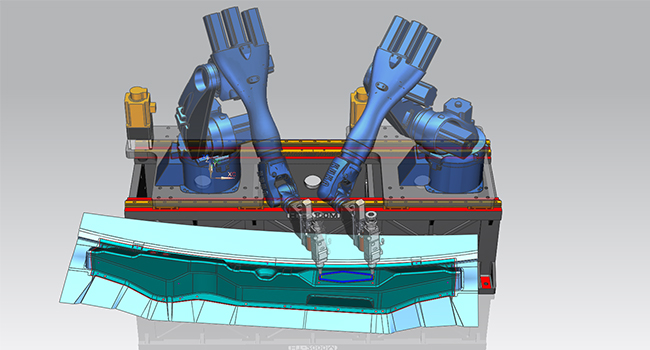

3.It integrates 3D vision, deep learning, motion planning and other technologies, adopts graphics without programming which can carry out modular drag, wiring, parameter configuration and non-programming functions.

4.Adopt aluminum alloy material, fully enclosed shell, protection class is IP65, 24V operation voltage, it has passed CEFCCVCCI and RoHS certification. Can better cope with dust, vibration, moisture, electromagnetic interference and other harsh environment.