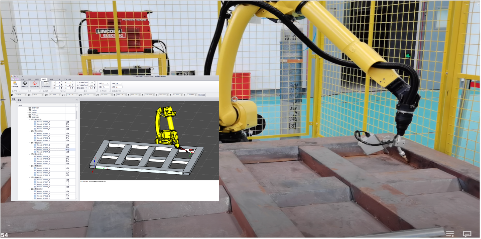

Industry application - carriage panel welding

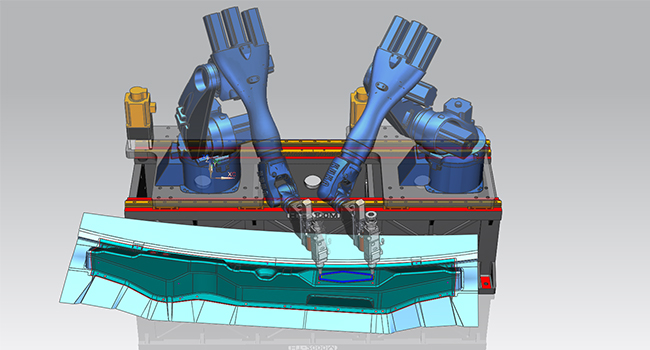

In the truck and dump truck carriage panel industry, the main characteristics of processing are multiple specifications and poor consistency, resulting in difficult programming and welding quality assurance. In terms of programming, it is extremely difficult to teach programming under the condition because there are multiple robots working at the same time in many welding workstations meanwhile welding robots have external axis.

Based on Minyue technology offline programming software,users can quickly program in two hours. At the same time, the consistency of workpiece can be effectively solved by combining laser vision welding seam tracking system. For carriage panel vertical weld and horizontal weld detection,after enhancement by Minyue technology, the parameters will adaptive to different weld seam widths automatically.At present, the Non-Teach solution can support.robot brands.such as KUKA,FANUC,ABB,Yaskawaandit has been applied in many areas already.