SmarEye WR laser seam tracking system is a 3D laser vision system for robotic welding developed by Beijing Minyue Technology Co., LTD. It supports robot brands such as KUKA, Yaskawa, ABB, Fanuc, Kawasaki, Siasun, Guangshu etc . The system consists of three parts: laser sensor, control host and software.

Short distance laser vision-SmartEye WR

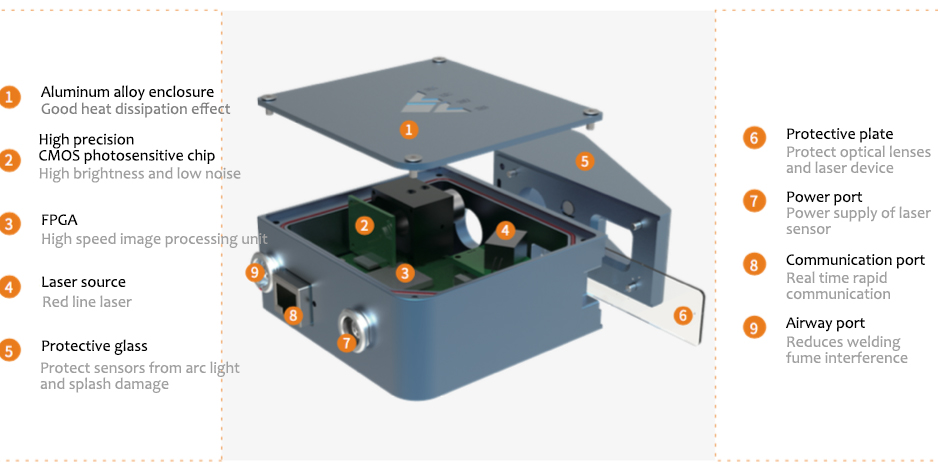

System composition

- Laser sensor is used to collect data

- Protective glass is used to protect optical lenses

- Fixed holder is used to install the laser sensor on welding torch

- Control host is used to configure and control laser sensor operation

- Communication cable is used to connect the sensor to control host

- Protective shield is used to protect sensor from arc light and splash.

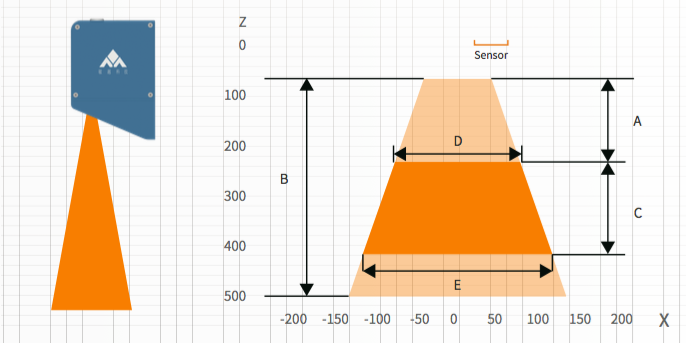

Main parameter

- A(mm):80 B(mm):180 C(mm):70 D(mm):50 E(mm):70

| Product parameter/Model |

SmartEye WR |

| Size |

85*75*34mm |

| Weight |

500g |

| detection period |

20ms |

| Detection accuracy of horizontal |

0.06mm |

| Detection accuracy of vertical |

0.1mm |

| Detection accuracy of butt weld |

0.3mm |

| Detection accuracy of lap weld |

0.2mm |

| Operation temperature |

-10~60℃ |

| Electromagnetic interference |

Strong anti-interference |

| Type of weld seam |

Fillet weld, splicing weld,VV weld,TT weld, heterosexual weld etc |

| Welding process |

Co2 welding,Arc welding etc |

| Characteristic |

Fast response and compact |

| Application fields |

Heavy machinery, piping, corrugated plate etc |